Abstract

Sourcing packaging for a hobby-focused business, whether for retail or a subscription service, presents a significant operational challenge that directly impacts profitability and brand perception. This analysis examines the multifaceted process of acquiring hobby boxes at wholesale pricing in the 2026 market. It delineates a structured, seven-point methodology for entrepreneurs and purchasing managers, beginning with the foundational task of defining specific packaging requirements based on the business model and product characteristics. The inquiry proceeds to explore methods for identifying and rigorously vetting potential suppliers, both domestic and overseas, emphasizing due diligence. A significant portion of the discussion is devoted to the strategic importance of customization as a tool for brand differentiation, covering structural design, printing, and finishing options. Further points address the technicalities of the quotation, negotiation, and logistics phases, including crafting effective requests for quotation (RFQ), navigating minimum order quantities (MOQ), and understanding international shipping terms. The objective is to provide a comprehensive framework for how to get hobby boxes wholesale, transforming a complex procurement task into a manageable strategic advantage.

Key Takeaways

- Define your box needs—size, material, and quantity—before contacting any suppliers.

- Thoroughly vet all potential wholesale suppliers, checking their history and certifications.

- Leverage customization to create a unique brand identity and unboxing experience.

- A detailed Request for Quotation (RFQ) is your most powerful tool for getting accurate pricing.

- Understanding how to get hobby boxes wholesale involves mastering negotiation and logistics.

- Build a long-term partnership with your supplier for better pricing and service over time.

- Always request a physical prototype to approve before committing to a full production run.

Table of Contents

- Point 1: The Foundational Blueprint: Defining Your Hobby Box Needs

- Point 2: The Search for a Partner: Identifying and Vetting Wholesale Suppliers

- Point 3: The Art of the Unboxing: Customization and Branding

- Point 4: The Language of Production: Mastering the Request for Quotation (RFQ)

- Point 5: The Dealmaker's Dialogue: Negotiating Price, Terms, and Timelines

- Point 6: The Global Journey: Navigating Logistics, Shipping, and Importation

- Point 7: The Enduring Alliance: Cultivating Long-Term Supplier Relationships

- Frequently Asked Questions

- A Final Reflection on Substance and Form

- References

Point 1: The Foundational Blueprint: Defining Your Hobby Box Needs

Before one can even begin to type "how to get hobby boxes wholesale" into a search bar, a period of introspection is required. The pursuit of wholesale packaging is not a treasure hunt where the prize is simply found; it is an architectural endeavor where you must first draw the blueprint. Without a clear and detailed understanding of your own needs, you are navigating without a compass, vulnerable to miscommunication, excessive costs, and a final product that fails to serve its purpose. This initial phase is the most critical, as the decisions made here will ripple through every subsequent step of the procurement process. It demands a rigorous examination of your business model, your product, and your financial realities.

The Subscription Box Model vs. The Retail Product Model

The first question you must answer is fundamental to your operational identity: What kind of business are you building? The packaging needs for a monthly subscription service are profoundly different from those for a standalone retail product sold online or on a shelf. The distinction is not merely semantic; it dictates size, material strength, and even the psychological purpose of the box itself.

A subscription box is a recurring experience. It often functions as its own shipper, a "mailer box," which must be durable enough to withstand the rigors of the postal system without an outer container. This necessitates the use of sturdy corrugated cardboard, typically E-flute or B-flute, which provides a protective cushion against drops, impacts, and compression. The value is cumulative, built through repeated positive experiences. The customer anticipates its arrival each month, so the box becomes a familiar, welcome guest. Its design must be consistent yet perhaps offer slight variations or "Easter eggs" over time to maintain excitement.

A retail product box, conversely, is often designed for shelf appeal and a singular, impactful unboxing moment. It might be a custom rigid box packaging for a high-end modeling kit or a beautifully printed folding carton for a set of crafting tools. These boxes are typically shipped to a retailer or a distribution center in a larger, plain master carton. Their primary role is not transit survival but visual seduction. They must compete in a crowded visual environment, using graphics, form, and texture to capture a potential buyer's attention in a matter of seconds. The material choice might prioritize a smooth, premium finish for high-resolution printing over the rugged durability of a mailer.

Consider the journey of each box. Does your box need to protect a single, fragile item on a journey from a warehouse directly to a customer's porch? Or does it need to sit elegantly on a brightly lit store shelf, whispering promises of the fun contained within? Answering this question clarifies your primary material and structural requirements.

| Feature | Subscription Hobby Box (Mailer) | Retail Hobby Box (Product Packaging) |

|---|---|---|

| Primary Function | Shipping & Unboxing Experience | Shelf Appeal & Unboxing Experience |

| Typical Material | Corrugated Cardboard (E-flute, B-flute) | Rigid Paperboard, Folding Carton, Corrugated |

| Structural Need | High durability, crush resistance | Premium finish, visual impact, structural integrity |

| Design Focus | Brand consistency, transit survivability | Eye-catching graphics, unique form, tactile feel |

| Shipping Method | Shipped individually via postal service | Shipped in bulk master cartons to retail/DC |

Sizing, Material, and Structural Requirements

With your business model defined, you can move to the specifics of the box itself. This is a process of meticulous measurement and material consideration. Start with the contents. Gather all the items that will go into your hobby box and arrange them. What is the most efficient layout? This will determine your internal length, width, and height dimensions. Always add a small amount of "air" or tolerance—a few millimeters on each side—to make packing and unpacking easier. A fit that is too tight can be frustrating for the user and risks damaging the contents.

Next, consider the weight of the items. A box containing heavy metal miniatures requires a stronger grade of paperboard or corrugated material than one holding lightweight yarn. This is where material specifications become vital. You will encounter terms like ECT (Edge Crush Test) for corrugated boxes, which measures stacking strength, or paperboard caliper (measured in points or 'pt'), which indicates thickness for folding cartons and rigid boxes. A 32 ECT corrugated box is a standard for many e-commerce shipments, while a luxury rigid box might be constructed from 80pt or 100pt paperboard for a feeling of substance and heft.

Think about the internal structure. Will your items be safe if they are loose inside the box, perhaps cushioned with crinkle paper? Or do they require a custom insert to hold them securely in place? For a hobby box with multiple delicate components—like a drone kit or a set of glass paint bottles—an insert is not a luxury; it is a necessity. Inserts can be made from die-cut corrugated cardboard, molded paper pulp for an eco-friendly option, or foam (like EVA) for maximum protection of high-value items. The design of the insert is as much a part of the blueprint as the box itself.

Projecting Volume and Establishing a Budget

The final piece of your internal blueprint is financial. You must move from the ideal to the possible by projecting your order volume and establishing a realistic budget. Wholesale pricing is predicated on economies of scale. The cost per box for 500 units will be dramatically higher than the cost for 5,000 units.

As a new business, this can feel like a difficult prediction. Start with a conservative but realistic sales forecast. If you are launching a subscription service, how many subscribers do you realistically anticipate in your first three to six months? If you are launching a retail product, what is the minimum order your retail partners will accept? This initial number will be your starting point for requesting quotes. It is wise to ask for pricing at several quantity tiers (e.g., 500, 1000, 2500, 5000 units). This shows the supplier you are planning for growth and helps you understand your cost structure as you scale.

Your budget must account for more than just the per-unit cost of the box. Create a spreadsheet and list all potential costs:

- The boxes themselves

- Custom printing plates or cutting dies (often a one-time fee)

- Prototyping/sampling fees

- Shipping from the supplier to your facility

- Any applicable taxes or import duties

Summing these up will give you a "landed cost" per box, which is the true cost you need to factor into your product's pricing. Without this comprehensive budget, you risk underpricing your product and erasing your profit margin. This careful financial planning is the final step in creating a robust blueprint, ensuring your search for how to get hobby boxes wholesale is grounded in economic reality.

Point 2: The Search for a Partner: Identifying and Vetting Wholesale Suppliers

Armed with a detailed blueprint of your needs, you can now begin the active search for a manufacturing partner. This stage is akin to casting for a critical role in a play. The supplier you choose will have an immense impact on your product quality, your brand reputation, and your bottom line. A great partner is a powerful asset, offering guidance, reliability, and quality. A poor partner can lead to delays, defects, and endless frustration. The process of how to get hobby boxes wholesale is, in essence, a process of finding the right collaborator. This requires a dual approach: first, a broad search to identify potential candidates, and second, a deep investigation to vet their suitability.

Domestic vs. Overseas Manufacturing: A Comparative Analysis

One of the first strategic decisions you will face is whether to source your hobby boxes domestically or from an overseas manufacturer, most commonly in Asia, and specifically China. There is no universally "correct" answer; the optimal choice depends entirely on your specific priorities regarding cost, speed, quantity, and customization.

Sourcing domestically in the USA or Europe offers several distinct advantages. The most significant is speed and communication. Lead times are shorter, shipping is faster and less complex, and you are operating in the same time zone and language, which simplifies communication immensely. It is also far easier to visit a factory for an in-person press check or quality inspection. For businesses that prioritize speed-to-market or require smaller initial order quantities, domestic suppliers are often the more practical choice. Furthermore, there is a marketing advantage to being able to claim your packaging is "Made in the USA" or "Made in Europe," which can appeal to certain consumer segments.

Overseas manufacturing, on the other hand, presents one overwhelming advantage: cost. The per-unit cost of a custom-printed box from a Chinese manufacturer can be substantially lower than from a domestic equivalent, particularly at higher volumes. This cost differential can be the deciding factor for a business's profitability. Moreover, the manufacturing ecosystem in regions like China is incredibly mature, offering a breathtaking range of capabilities, materials, and finishing options that might be harder to find or more expensive domestically. Companies like TOPACK Paper Boxes have extensive experience working with international clients and can manage highly complex projects. The trade-offs, however, are significant. Lead times are much longer, shipping is a complex logistical puzzle involving freight and customs, and communication can be challenging across time zones and potential language barriers.

| Factor | Domestic Supplier (USA/Europe) | Overseas Supplier (e.g., China) |

|---|---|---|

| Per-Unit Cost | Higher | Lower, especially at high volumes |

| Minimum Order Quantity (MOQ) | Generally Lower | Generally Higher |

| Lead Time | Shorter (2-6 weeks) | Longer (4-8 weeks production + 4-6 weeks shipping) |

| Shipping | Simpler, faster, cheaper | Complex, slower, requires freight/customs |

| Communication | Easier (same time zone/language) | Can be challenging (time zones, language) |

| Customization Options | Good, but may be more limited/expensive | Extremely broad and cost-effective |

| Factory Oversight | Easier to visit and inspect | Difficult and expensive to visit |

Utilizing B2B Marketplaces and Industry Directories

Your search for potential suppliers will likely begin online. There are several key resources that serve as gateways to the world of wholesale packaging manufacturers.

-

B2B Marketplaces: Websites like Alibaba are the giants of global sourcing, connecting buyers with millions of manufacturers, primarily from Asia. They are an excellent tool for finding a wide array of suppliers and getting a preliminary sense of pricing. However, they require careful navigation. The sheer number of listings can be overwhelming, and it is crucial to use the platform's tools to filter for verified, experienced suppliers with good ratings. Thomasnet is a U.S.-based equivalent, focusing on North American industrial suppliers, making it a prime resource for finding domestic partners.

-

Industry-Specific Directories: Many packaging industry associations maintain directories of their members. A search for organizations like the Paperboard Packaging Council or the Independent Packaging Association can yield lists of reputable manufacturers. These suppliers have often been pre-vetted to some extent by virtue of their membership.

-

Search Engines: A targeted search engine query can be surprisingly effective. Instead of a generic search, be specific. Use phrases like "custom rigid box manufacturer USA," "corrugated mailer box supplier Europe," or "wholesale cosmetic box printing China." This will help you bypass general resellers and find direct manufacturers.

As you compile a list of 10-15 potential suppliers, create a spreadsheet to track them. Note their location, their stated specialties (e.g., rigid boxes, corrugated printing), their years in business, and any certifications they list, such as ISO 9001 (for quality management) or FSC (for sustainable sourcing).

The Art of the Supplier Background Check

Identifying a potential supplier is only the beginning. The vetting process is where you separate the contenders from the pretenders. This is an investigative process that requires diligence and a healthy dose of skepticism.

First, conduct a thorough review of their website. Does it look professional and detailed? A well-established manufacturer will have a comprehensive site showcasing their capabilities, machinery, and portfolio of past work. Look for case studies or galleries that show projects similar to yours. Are the photos of their own factory and products, or are they generic stock images? A site that provides an in-depth look into their process, such as a guide on how to make a paper box, demonstrates expertise and transparency.

Next, search for third-party reviews or testimonials. Look for the company's name on sourcing forums, Reddit communities (like r/fulfillment or r/smallbusiness), or B2B review sites. What are other businesses saying about their experience? One negative review is not necessarily a deal-breaker, but a consistent pattern of complaints about quality, delays, or poor communication is a major red flag.

Finally, engage them directly but start with a test. Before sending your full RFQ, send a simple inquiry. Ask a specific question about their capabilities, for instance, "Can you produce a drawer-style rigid box with a ribbon pull and a beveled edge?" Pay close attention to their response. How quickly do they reply? Is the answer clear, professional, and written in fluent English? This initial interaction is a microcosm of what a future working relationship might look like. A supplier who is slow or unclear at this stage is unlikely to improve when you have a complex order on the line. This careful, multi-pronged vetting process is fundamental to finding a reliable partner and is a non-negotiable step in learning how to get hobby boxes wholesale successfully.

Point 3: The Art of the Unboxing: Customization and Branding

In the contemporary e-commerce landscape, the box is no longer a mere vessel for transit. It has evolved into a primary channel for brand communication, a silent storyteller that shapes the customer's first physical interaction with your product. The unboxing experience, a term that has transcended niche forums to become a mainstream marketing concept, refers to the sequence of actions and emotional responses a customer has when opening a package (Lopes et al., 2021). For a hobby box, this experience is paramount. It is the curtain rising on a new project, a new skill, a new adventure. Investing in customization is not an indulgence; it is a strategic investment in customer delight, retention, and organic marketing. When you master customization, you are no longer just buying boxes; you are commissioning brand ambassadors.

Moving Beyond the Brown Box: The Power of Custom Printing

The most fundamental level of customization is printing. A plain brown or white box is a missed opportunity, a blank canvas left unpainted. Custom printing transforms the box from a utility item into a piece of marketing collateral.

The choice of printing method is your first consideration.

- Flexographic Printing (Flexo): This method is most common for printing directly onto corrugated cardboard. It uses flexible rubber plates and is highly efficient for large runs of simple, one or two-color designs. Think of the Amazon logo on their standard mailers. It is cost-effective but less precise for complex, multi-color images.

- Offset Lithographic Printing (Litho): For high-resolution, photo-quality graphics, litho-lamination is the superior process. Here, your design is printed onto a thin sheet of paper using traditional offset printing, which offers exceptional color accuracy and detail. This printed sheet is then laminated onto the corrugated or rigid board before it is cut and folded. The result is a box with the strength of corrugated but the visual appeal of a high-end magazine. This is the method used for most retail-quality packaging, from board games to electronics.

- Digital Printing: For smaller quantities or projects requiring variable data, digital printing is an increasingly viable option. It prints directly onto the board without the need for plates, allowing for cost-effective short runs and even personalization on every box. The quality has improved immensely and can rival offset for many applications.

Think about what you want your printing to achieve. Is it simply your logo for brand recognition? Or is it a full-color, wraparound design that tells a story or evokes a specific mood? A hobby box for a fantasy role-playing game could be printed to look like an ancient tome, while a box for a watercolor painting kit could feature a beautiful, soft-focus floral design. The printing sets the stage and builds anticipation for the contents.

Structural Customization: Inserts, Windows, and Unique Shapes

Beyond surface printing, the very structure of the box can be customized to enhance both function and form. This is where you can truly innovate and create a memorable and practical experience for your customer.

Custom inserts, as mentioned earlier, are vital for protection, but they are also a tool for presentation. An insert choreographs the reveal. Instead of a jumble of items, the customer is presented with each component nestled in its own perfectly sized compartment. This communicates care, organization, and quality. Imagine a hobby box for building a miniature ship. An insert that holds the hull, the masts, and the tiny rigging components separately not only protects them but also presents them in a logical, accessible way, reducing frustration and enhancing the building experience.

Windows are another powerful structural element. A die-cut window, covered with a thin, clear film, offers a tantalizing glimpse of the product inside. This can be incredibly effective for retail hobby boxes, as it allows customers to see the quality of a key component—the vibrant colors of yarn, the detailed sculpt of a miniature, the texture of a piece of fabric—without opening the box. The shape of the window itself can be a branding element, echoing the shape of your logo or a key item in the box.

Do not feel constrained by the standard rectangular prism. While unique shapes are more expensive to design and produce due to the need for custom cutting dies, they can be a powerful differentiator. A box for a gardening hobby kit could be shaped like a hexagon to evoke a honeycomb, or a box for a magic kit could be shaped like a top hat. A unique structure makes the packaging itself an object of interest, something a customer might keep long after the contents are used.

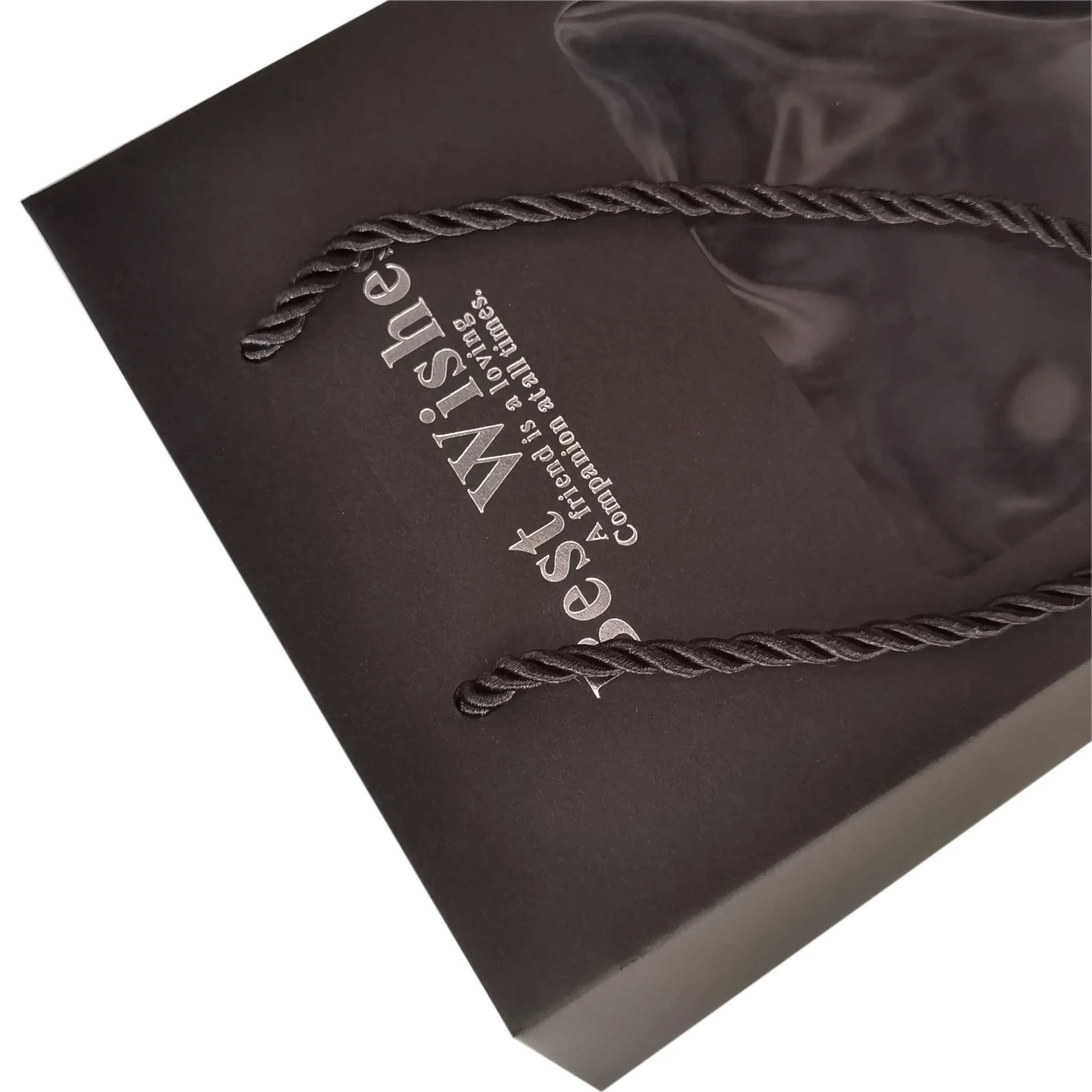

Finishing Touches: Lamination, Foiling, and Embossing

The final layer of customization involves special finishes that appeal to the senses of touch and sight. These are the details that elevate a package from good to luxurious, creating a haptic experience that reinforces the premium quality of your brand.

-

Lamination: After printing, a thin film can be applied to the paper. A gloss lamination creates a shiny, vibrant look. A matte lamination offers a sophisticated, non-reflective finish. But for a truly premium feel, consider a soft-touch or velvet lamination. This finish has a unique, rubbery-smooth texture that feels incredibly luxurious and invites touch. It creates a powerful, memorable tactile impression.

-

Foil Stamping: This process uses a heated die to press a metallic or pigmented foil onto the surface. It is used to create brilliant, reflective logos and accents in gold, silver, copper, or a wide range of colors. A simple gold foil logo on a matte black box is a classic signifier of high-end quality.

-

Embossing & Debossing: These techniques alter the surface of the paper itself. Embossing uses a die to press a design upwards, creating a raised, 3D effect. Debossing presses the design downwards, creating an indented impression. These finishes add a subtle, tactile richness. Running a thumb over an embossed logo creates a physical connection to the brand.

-

Spot UV: This technique involves applying a high-gloss UV coating to a specific "spot" on the box, while the rest of the surface has a matte finish. This creates a striking contrast in texture and sheen, drawing the eye to a logo, image, or pattern.

These finishing touches are not merely decorative. They are sensory cues that communicate value. The weight of a rigid box, the satisfying snap of a magnetic closure, the unexpected softness of a velvet laminate—these details work together to build a perception of quality before the customer even sees the product. This is the essence of experiential branding and a critical consideration in your journey of how to get hobby boxes wholesale.

Point 4: The Language of Production: Mastering the Request for Quotation (RFQ)

After defining your needs, identifying potential partners, and envisioning your ideal customized box, you must transition from the conceptual to the commercial. This is achieved through the Request for Quotation, or RFQ. The RFQ is the single most important document you will create in the procurement process. It is not simply a request for a price; it is a comprehensive specification sheet that communicates your exact needs to a potential supplier. A detailed, professional RFQ is the key to receiving accurate, comparable quotes. A vague or incomplete RFQ will result in vague, incomparable quotes, wasted time, and endless back-and-forth communication. Mastering the RFQ is mastering the language of production.

Crafting a Detailed and Professional RFQ

Think of your RFQ as the complete blueprint you created in Point 1, now translated into a standardized format for manufacturers. Your goal is to leave no room for ambiguity or assumption. The supplier should be able to read your RFQ and know exactly what you want to create. Your document should be clearly organized and include the following sections:

- Introduction: Briefly introduce your company and the purpose of the hobby box (e.g., "We are a new subscription service for miniature painters and are seeking a quote for our monthly mailer box.").

- Contact Information: Your name, company name, email, phone number, and shipping address.

- Box Style: Be specific. Use industry terms. Is it a "Regular Slotted Carton (RSC)," a "Roll End Tuck Top (RETT) mailer," a "Two-Piece Lid and Base Rigid Box," or a "Drawer-Style Slipcase"? If you have a reference image or a dieline from a designer, include it.

- Dimensions: Provide the internal dimensions in Length x Width x Height. Specify the unit of measurement clearly (e.g., millimeters, inches).

- Material Specifications: This is critical. For a corrugated box, specify the flute type (e.g., E-flute) and the paper color (e.g., Kraft, White, or KRAFT outside/White inside). For a rigid box, specify the thickness of the chipboard (e.g., 80pt / 2mm) and the type of wrap paper (e.g., 157gsm art paper).

- Printing & Artwork: Specify the number of colors to be printed (e.g., CMYK full color, or 2 Pantone spot colors). State whether printing is on the outside, inside, or both. Mention that you will provide print-ready artwork in Adobe Illustrator (.ai) or PDF format.

- Finishing & Add-ons: List every special finish you require. For example: "Matte lamination on all printed surfaces," "Gold foil stamping on the logo on the lid," "Embossing on the company name," "Spot UV on background pattern." Include requirements for inserts, window patches, or ribbon pulls.

- Quantities: Request pricing for several tiers. For example: "Please provide a quote for quantities of 1,000, 2,500, and 5,000 units."

- Shipping Information: State your final delivery address and ask for the shipping costs to be quoted separately.

- Timeline: Ask the supplier to provide an estimated timeline for mass production and for the production of a physical sample.

Organize this information in a clean document (a PDF is ideal) and attach any relevant files, such as a low-resolution version of your artwork or a structural diagram.

Understanding Minimum Order Quantities (MOQs)

When you send out your RFQs, one of the first responses you will get, especially if your requested quantity is low, will concern the supplier's Minimum Order Quantity, or MOQ. The MOQ is the smallest number of units a factory is willing to produce in a single production run. This is not an arbitrary number. It is determined by the economics of production. Setting up the printing presses, cutting dies, and assembly lines for a custom box involves significant time and labor. These setup costs are the same whether the factory produces 500 boxes or 5,000. To be profitable, the factory must produce enough units to amortize these setup costs effectively.

For custom-printed corrugated mailers, MOQs from domestic suppliers might start around 500-1,000 units. From overseas suppliers, MOQs are often higher, typically starting at 1,000 units. For more complex rigid boxes, the MOQ might be similar, as the labor-intensive assembly process necessitates a certain volume to be efficient.

What if your required quantity is below the supplier's MOQ? You have a few options:

- Negotiate: Sometimes, a supplier might be willing to accept a lower MOQ for a first-time customer, but they will almost certainly charge a higher per-unit price to cover their setup costs.

- Order More: If you are confident in your sales projections, it might be more cost-effective in the long run to meet the MOQ and benefit from a lower per-unit cost. This is a cash flow consideration.

- Simplify: A highly complex box with multiple finishes will have a higher MOQ. Simplifying the design—for instance, by reducing the number of print colors—might allow the supplier to lower the MOQ.

- Find a Different Supplier: Some manufacturers specialize in short-run production, particularly those who rely heavily on digital printing. They will have higher per-unit costs but much lower MOQs, which can be ideal for a new business testing the market.

The Importance of Prototyping and Sampling

Within your RFQ, you must insist on a prototyping stage. Never, ever proceed to mass production without first approving a physical sample of your box. No matter how detailed your specifications or how realistic a 3D digital proof looks, nothing can replace the experience of holding the actual box in your hands.

There are several types of samples:

- Stock Sample: A sample of a previous job the factory has done for another client. This is useful for judging their general print quality and construction, but it is not your box.

- Unprinted (Structural) Sample: A box made to your exact size and material specifications but with no printing. This allows you to test the structure, the fit of your products, and the strength of the box.

- Fully Printed, Assembled Pre-Production Sample: This is the gold standard. It is a complete, finished version of your box, exactly as it will appear in the mass production run. It is your final opportunity to check colors, finishes, construction, and overall quality.

There is almost always a fee for producing a pre-production sample, often ranging from $100 to $500, depending on the complexity. This fee may sometimes be credited back to you if you proceed with a mass production order. Do not think of this as a cost; think of it as the most valuable insurance policy you can buy. A $300 sample that allows you to catch a critical color error or a structural flaw can save you from a disastrous $30,000 production run of unusable boxes. This step is a non-negotiable part of the professional approach to how to get hobby boxes wholesale.

Point 5: The Dealmaker's Dialogue: Negotiating Price, Terms, and Timelines

Once you have received quotes from your vetted suppliers, the process enters a new phase: negotiation. This is not an adversarial confrontation but a structured dialogue aimed at reaching a mutually beneficial agreement. Your goal is to secure the best possible value, which encompasses not just price, but also favorable payment terms, realistic production timelines, and a clear understanding of all responsibilities. A successful negotiation establishes the foundation for a healthy, long-term partnership. Approaching this dialogue with preparation, professionalism, and a clear understanding of your own leverage is key to navigating this crucial stage.

Strategies for Effective Price Negotiation

The price quoted by a supplier is rarely their final offer. It is typically a starting point. However, effective negotiation is more nuanced than simply asking for a 10% discount. Your ability to negotiate successfully depends on the leverage you bring to the table.

-

The Power of Multiple Quotes: This is your greatest asset. By having quotes from three or more suppliers for the exact same specifications, you have a clear understanding of the market rate. You can professionally and respectfully inform a preferred supplier that their price is higher than others you have received. For example: "We are very impressed with your quality and communication, but your quoted price of $2.80/unit is about 15% higher than other quotes we have from similarly qualified manufacturers. Is there any flexibility in your pricing to help us close this gap?" This demonstrates you have done your homework and are a serious buyer.

-

Negotiate on Volume: Use the tiered pricing you requested in your RFQ. You might say, "Your price for 1,000 units is a bit high for our budget. However, your price for 2,500 units is much more competitive. We are willing to commit to the larger order of 2,500 units if you can offer us that price for an initial order of 1,500 units, with a commitment to reorder within six months." This shows a willingness to be a long-term partner.

-

Discuss Specifications: If a supplier's price is firm, explore cost-saving adjustments. Ask your sales representative for their expert opinion: "We need to get the unit cost below $2.50. Based on our design, what changes would you recommend to help us reach that target? Could we use a slightly lighter paperboard without compromising the structure? Would changing from two Pantone colors to a CMYK build be more cost-effective?" This collaborative approach shows respect for their expertise and can often uncover savings you had not considered.

-

Understand the Value Proposition: Do not focus solely on the lowest price. A supplier who quotes 10 cents less per box but has poor communication and a history of delays will cost you far more in the long run. Consider the total value: their responsiveness, their willingness to provide samples, their quality control processes. Sometimes it is worth paying a slight premium for a reliable, high-quality partner.

Decoding Payment Terms (T/T, L/C, etc.)

The payment schedule is as important a point of negotiation as the price itself. For a first-time order, especially with an overseas supplier, you will almost never be offered "Net 30" terms (where you pay 30 days after receiving the goods). The standard practice is a deposit upfront with the balance due at a later stage.

The most common payment structure is a Telegraphic Transfer (T/T). A typical arrangement for a new customer is:

- 30-50% Deposit: Paid upfront before any production begins. This allows the factory to purchase the raw materials for your job.

- 70-50% Balance: The remaining balance is due at a specific milestone. This is a key point of negotiation. The supplier will prefer the balance to be paid upon completion of production, before the goods are shipped. As a buyer, you should push for the balance to be due upon your receipt and approval of a copy of the Bill of Lading. The Bill of Lading is the official shipping document that proves your goods have been loaded onto the vessel. Paying the balance at this stage provides you with a degree of security, as it confirms your order has actually shipped before you release the final payment.

For very large orders (typically over $50,000), a Letter of Credit (L/C) might be used. An L/C is a formal guarantee from your bank to the supplier's bank, promising that payment will be made once certain conditions (like providing shipping documents) are met. It offers a high degree of security for both parties but is also complex and involves bank fees, making it less common for smaller orders.

Never agree to pay 100% upfront. This leaves you with zero leverage if there are quality issues or delays with your order. A deposit/balance structure is the industry standard and provides a fair balance of risk for both buyer and seller.

Establishing Clear Production and Shipping Schedules

Your time is money. Delays in receiving your packaging can halt your entire business operation. It is vital to negotiate and document a clear and realistic timeline for your order.

Your timeline should have two key components:

-

Mass Production Lead Time: This is the time it takes for the factory to manufacture your boxes, from the moment you approve the pre-production sample and pay the deposit. This can range from 2 to 8 weeks depending on the complexity of your box and the factory's current workload. Ask them to commit to a firm "ex-factory date," which is the date your order will be fully packed and ready for pickup.

-

Shipping Time: This is the time it takes for the goods to travel from the factory to your door. For domestic suppliers, this might be a few days of ground shipping. For overseas suppliers, this is a much longer process. Ocean freight from China to the USA or Europe typically takes 4-6 weeks. Air freight is much faster (5-10 days) but is prohibitively expensive for a bulk order of boxes.

Work backward from your "in-hand" date. If you need your boxes in your warehouse by July 1st, and you account for 5 weeks of ocean freight and 1 week for customs clearance, your goods must ship from the factory no later than mid-May. If the production lead time is 6 weeks, you must approve your sample and pay your deposit by the beginning of April. This simple exercise in backward planning is essential for avoiding last-minute panic and ensuring your packaging arrives when you need it. Get these dates in writing in your Purchase Order or contract.

Point 6: The Global Journey: Navigating Logistics, Shipping, and Importation

For any business sourcing from overseas, the moment production is complete is not the end of the process, but the beginning of a new, often bewildering, journey. The task of how to get hobby boxes wholesale extends far beyond the factory floor. It involves moving thousands of pounds of product across oceans, through ports, and past customs checkpoints. This is the world of logistics, and for the uninitiated, it can be a minefield of confusing acronyms, hidden costs, and bureaucratic hurdles. However, by understanding a few key concepts and partnering with the right professionals, you can demystify the process and ensure your goods arrive safely, legally, and without costly surprises.

Understanding Incoterms (FOB, EXW, DDP)

When you receive a price quote from an overseas supplier, it will almost always be accompanied by a three-letter acronym like "FOB," "EXW," or "DDP." These are Incoterms, a set of globally recognized rules published by the International Chamber of Commerce that define the responsibilities of the seller and the buyer in an international transaction. They specify who is responsible for paying for and managing the shipment, insurance, and customs clearance. Understanding the difference is absolutely critical.

-

EXW (Ex Works): This term places the maximum responsibility on you, the buyer. The price quoted is simply the cost of the goods. The seller's only job is to make your boxes available for pickup at their factory. From that point on, you are responsible for everything: arranging for a truck to pick up the goods from the factory, transporting them to the port, clearing them for export, the ocean freight, insurance, customs clearance in your country, and final delivery to your door. While it offers you complete control, it is the most complex option and is not recommended for beginners.

-

FOB (Free On Board): This is the most common Incoterm for overseas sourcing and offers a good balance of responsibility. The FOB price includes the cost of the goods PLUS the cost of transporting them from the factory to the designated port of departure and loading them "on board" the shipping vessel. Once the goods are on the ship, the responsibility and risk transfer to you. You are then responsible for the main ocean freight, insurance, and all the costs and procedures associated with importing the goods into your country.

-

DDP (Delivered Duty Paid): This term places the maximum responsibility on the seller. The DDP price is an all-inclusive price that covers the cost of the goods, all shipping costs, and all customs duties and taxes required to deliver the goods directly to your specified final address. It is the simplest option for the buyer, as the seller handles the entire logistical process. However, it is also the most expensive, as the seller will build a significant margin into the DDP price to cover their costs and risks. It also gives you zero visibility or control over the shipping process.

For most small to medium-sized businesses, FOB is the recommended term. It allows you to work with your own chosen shipping partner (a freight forwarder) who represents your interests, giving you control over the most expensive part of the journey while leaving the local, pre-export logistics to the supplier who knows their own country best.

Working with Freight Forwarders

A freight forwarder is your single most important partner in the logistics process. Think of them as a travel agent for your cargo. They are experts who manage the complex logistics of international shipping on your behalf. You do not need to book a container with a shipping line or file customs paperwork yourself; your freight forwarder does all of this.

When you have an order on an FOB basis, your process will look like this:

- You find and hire a freight forwarder. Get quotes from several.

- You provide your freight forwarder with your supplier's contact information and the details of your shipment (number of cartons, total weight, and volume).

- Your freight forwarder coordinates with your supplier to book space for your cargo on a shipping vessel.

- Your supplier delivers the goods to the port, as per the FOB terms.

- Your freight forwarder manages the ocean freight journey.

- When the ship arrives at the port in your country, your freight forwarder's team manages the import process. This includes filing the necessary customs declarations and paying any duties and taxes on your behalf (which they will invoice to you).

- Once the goods have cleared customs, the freight forwarder arranges for final delivery from the port to your warehouse or facility.

A good freight forwarder provides not just a service, but also invaluable advice. They can help you understand your duty rates, advise on the best shipping routes, and troubleshoot any problems that arise.

Customs, Duties, and Taxes Explained

Every country has a customs agency that controls the flow of goods across its borders. When your hobby boxes arrive, they must be "cleared" by customs before they can be released to you. This process involves declaring what the goods are and paying any applicable duties and taxes.

-

Customs Duties (or Tariffs): This is a tax levied on imported goods. The amount of duty you pay is determined by the product's HS Code (Harmonized System Code), its country of origin, and its declared value. The HS Code is a globally standardized code that classifies products. For example, "Boxes, cartons, and cases of corrugated paper or paperboard" have a specific HS code. Your freight forwarder or a licensed customs broker can help you determine the correct HS code and the corresponding duty rate for your product. These rates can change, so it is important to get current information.

-

Value Added Tax (VAT) or Goods and Services Tax (GST): In addition to duties, many countries (like those in the EU and the UK) levy a VAT on imported goods. In the USA, there is no federal VAT, but there are other fees like the Merchandise Processing Fee (MPF).

These costs are significant and must be factored into your landed cost calculation. A failure to budget for duties and taxes can turn a profitable order into a loss-making one. Your freight forwarder will typically pay these fees on your behalf to expedite customs clearance and then include them on their final invoice to you. This is a complex but unavoidable part of the process, and relying on professional expertise is the only sensible path forward.

Point 7: The Enduring Alliance: Cultivating Long-Term Supplier Relationships

The final point in our journey of how to get hobby boxes wholesale is perhaps the most overlooked, yet it holds the key to sustainable, long-term success. The process of sourcing should not be viewed as a series of discrete, transactional events. It should be seen as the beginning of a strategic partnership. The goal is not just to buy one batch of boxes, but to build an enduring alliance with a manufacturer who understands your business, anticipates your needs, and grows with you. A strong supplier relationship is a competitive advantage that pays dividends in the form of better pricing, preferential treatment, improved quality, and collaborative innovation over time.

Communication as the Cornerstone of Partnership

The foundation of any strong relationship, business or personal, is clear, consistent, and respectful communication. This is doubly true when dealing with a manufacturing partner, especially one located across the globe.

-

Be Proactive and Organized: Do not wait for problems to arise. Provide your supplier with clear forecasts of your future needs. If you anticipate a large holiday order, give them several months' notice. Keep all your communication organized by project or purchase order number. A simple, polite, and professional email will always yield better results than an angry, demanding one.

-

Understand Cultural Nuances: When working with overseas suppliers, particularly in Asia, it is helpful to understand that business culture can be more relationship-oriented. Building rapport is important. A brief, friendly opening to an email before getting down to business can go a long way. Concepts like "saving face" are important; public criticism or aggressive confrontation is often counterproductive. Frame feedback constructively and privately.

-

Establish a Primary Point of Contact: You should have a dedicated sales representative or account manager at the factory. This person is your advocate and your primary channel of communication. Cultivate a good working relationship with them. They are the ones who will push your order through when the factory is busy or help you solve a problem quickly.

-

Use Communication Tools Wisely: Email is the standard for formal documentation like purchase orders and official approvals. For quick, informal questions, many suppliers now use messaging apps like WhatsApp or WeChat, which can be very efficient for overcoming time zone differences. However, always confirm any critical decisions or changes in a follow-up email to ensure there is a written record.

Providing Constructive Feedback for Continuous Improvement

No supplier is perfect, and it is likely that at some point, an order may have minor issues. The way you handle this feedback can either strengthen or damage your relationship.

When a problem occurs, do not lead with accusations. Lead with data. If some boxes have a printing defect, take clear photographs. If a percentage of a shipment was damaged, document it thoroughly. Present this evidence to your supplier in a calm, factual manner. For example: "Hello [Rep Name], we have received our order PO-101. The overall quality is excellent, thank you. However, we have found that in approximately 5% of the cartons we have inspected, the foil stamping is slightly misaligned. I have attached photos for your reference. Can you please advise on how we can prevent this on our next production run?"

This approach achieves several things. It acknowledges the good work they did, which preserves the relationship. It provides clear, undeniable evidence of the problem. It frames the issue as a collaborative challenge ("how can we prevent this") rather than an accusation. A good supplier will appreciate this professional approach and will often offer a credit on your next order or work with you to find a solution. This feedback loop is essential for continuous improvement and ensures that each production run is better than the last.

Planning for Scalability and Future Orders

A true partnership is forward-looking. As your hobby box business grows, your packaging needs will evolve. You may need larger quantities, different box sizes for new product lines, or more sophisticated printing and finishing options. A good supplier relationship makes scaling a smooth process rather than a series of crises.

Share your vision with your supplier. Let them know your growth plans. This allows them to plan their own capacity and material purchasing. As you become a larger, more consistent customer, your negotiating power increases. You can leverage your history of timely payments and consistent orders to negotiate better pricing, more favorable payment terms (perhaps moving from 50% deposit to 30%), or priority scheduling during busy seasons.

Think of your supplier as an extension of your own team. They have deep expertise in packaging manufacturing. Ask for their advice. Before launching a new box, send them the concept and ask for their input. They might suggest a more cost-effective material or a structural improvement that enhances the user experience. This collaborative approach can lead to genuine innovation, resulting in a better product for your customers and a more efficient process for your business. By investing in the relationship, you transform a simple supplier into a valuable strategic partner, ensuring your ability to source high-quality hobby boxes wholesale for years to come.

Frequently Asked Questions

What is the most significant hidden cost when getting hobby boxes wholesale from overseas?

The most significant and often underestimated cost is inbound logistics, which includes ocean freight, insurance, customs duties, and domestic delivery from the port. These costs are not part of a standard FOB price and can add a substantial percentage (often 20-40%) to the factory cost of your boxes. It is absolutely vital to get a full "landed cost" estimate from a freight forwarder before placing your order.

How can I ensure the print colors on my box are accurate?

The best way to ensure color accuracy is to use the Pantone Matching System (PMS). Provide your supplier with the specific PMS color codes for your brand. For the most critical applications, you can also request a "drawdown" (a sample of the ink on your chosen paper stock) or, even better, pay for a physical pre-production prototype. This allows you to see and approve the exact colors before committing to the full production run.

Is it cheaper to source boxes from a manufacturer on Alibaba or directly from their website?

Often, the pricing will be very similar. However, initiating contact through a platform like Alibaba can sometimes provide an extra layer of security through their Trade Assurance program. The main advantage of working directly with a manufacturer found via their own website is that you are often dealing with a more established company that has invested in its own brand presence and may have more experienced sales staff dedicated to direct international clients. The best approach is to identify suppliers through both channels and compare their communication, quality, and pricing.

What happens if my boxes arrive damaged?

First, document everything immediately with clear photos of the damaged shipping cartons and the boxes inside. Contact both your supplier and your freight forwarder. If you purchased freight insurance (which you always should), your freight forwarder will help you file a claim. Your recourse with the supplier depends on your relationship and the cause of the damage. If it was due to inadequate packaging for transit, a good supplier will often offer a credit on a future order.

Can I get a refund if I am unhappy with the quality of my wholesale boxes?

Getting a direct cash refund from an overseas supplier is extremely difficult and rare. This is why the prototyping and quality control process is so critical. Your power lies in approving the pre-production sample and in structuring your payment terms so that you do not release the final balance until you have proof of shipment and, ideally, a quality control inspection report. If there are minor issues, the standard resolution is a discount or credit on your next order, not a refund.

How do I find a reliable freight forwarder?

Start by asking for recommendations from other business owners in your network or in online communities related to e-commerce and sourcing. You can also use online freight marketplaces like Flexport, Freightos, or Shippo to get and compare quotes from multiple vetted forwarders. Look for a forwarder who is responsive, communicates clearly, and has experience with imports from your supplier's country to your own.

A Final Reflection on Substance and Form

The endeavor of procuring hobby boxes at a wholesale scale is, at its heart, an exercise in navigating the intricate relationship between substance and form. The journey we have mapped out, from the initial blueprint of needs to the cultivation of an enduring partnership, reveals that a box is never just a box. It is the physical manifestation of a brand's promise, the tangible first impression that sets the stage for the experience within. The substance—the caliper of the paperboard, the strength of the corrugated flute, the precision of the die-cut insert—provides the necessary function of protection. It ensures the product arrives safely, a fundamental but insufficient condition for success.

The form—the vibrancy of the printed color, the tactile surprise of a soft-touch finish, the satisfying snap of a magnetic closure—is what elevates the object from a container to a communication. It is through form that we create delight, build anticipation, and communicate a value that transcends the sum of the contents. The process of how to get hobby boxes wholesale is therefore not a simple procurement task. It is a strategic discipline that requires an architect's foresight, an investigator's diligence, a diplomat's tact, and a logistician's precision. By mastering these domains, an entrepreneur transforms a cost center into a powerful engine for brand loyalty, customer satisfaction, and sustainable growth. The resulting package becomes more than a container; it becomes an integral part of the hobby itself, the cherished chest that holds the tools of creation and joy.

References

Cospaks. (2025). Definitive Guide to Paperboard Box Packaging: Sourcing. Cospaks.

Lopes, S., Faria, F., & Santos, C. (2021). The unboxing experience: A new challenge for logistics and marketing. In P. M. F. M. P. De M. A. M. De C. A. M. D. L. Azevedo (Ed.), Proceedings of the 2nd International Conference on Marketing and Communication (pp. 52-60).

Meiyin. (2025). The Complete Guide to Packaging Cardboard Types: From Corrugated to Specialty Grades. Meiyin Package.

Ncube, L. K., Ude, A. U., Ogunmuyiwa, E. N., Zulkifli, R., & Beas, I. N. (2024). The function and properties of common food packaging materials and their suitability for reusable packaging: The transition from a linear to circular economy. Cleaner Materials, 11, 100257.

Patil, A. Y. (2025). Advancements in Packaging Materials: Trends, Sustainability, and Future Prospects. Journal of Polymers and the Environment, 5, 2959–2990. https://doi.org/10.1007/s43615-025-00586-4

Pirsa, S. (2024). Cellulose-based cartons: production methods, modification, and smart/active packaging. Cellulose, 31(6), 3421–3445.

Zhibang Packaging. (2023). Rigid Boxes vs. Folding Cartons: A Complete Comparison. Zhibang Packaging.